SDV transforms the automotive experience at every level

Among the various trends that are radically changing the experience of building and driving vehicles, software development is a major focus.

Lea este informe en castellano

Report published in AutoRevista 2.403

Helen Clergeau, Head of Software Defined Vehicle at Continental, says that “changing the design and development of a passenger car using specialized vehicle definition software can improve efficiency, innovation and product quality. Modern vehicle definition software can enable the definition of vehicle configurations and variants early in the design phase. This can help towards a holistic vehicle architecture design as we see with the transformation towards a server-zone architecture bringing the integration of Body, Chassis, Powertrain as well as ADAS, infotainment and connectivity systems The performance and cost efficiency can also be improved by simulating design decisions that impact the different system requirements”.

Clergeau comments “the update of car functions over the vehicle lifecycle brings an advantage through several aspects: feature upgrade for example improved or updated navigation; update of issues in the field through (OTA) over the air updates, so less need for the car owner to visit the garage as well as the ability to do predictive maintenance; security updates over the lifetime can be ensured to ensure cyber security evolution is taken into account as well as updates necessary for compliance”.

“To enable updating car functions throughout the vehicle lifetime”, she adds, “some considerations are necessary, to name a few: modular and scalable architecture, so that the functions can be updated independently; cloud- Connected with over the air (OTA) capability including the ability to deploy the software remotely and therefore a secure backend infrastructure for update management; strong security compliance to protect from unauthorized access, software update verification, and adherence to cyber security standards; and hardware and middleware abstraction to decouple application software from specific hardware implementations. For example, semantic interfaces abstracting components and functions (COVESA)”.

For Helen Clergeau, “the SDV trend will bring transformation in the direction of having a software driven lifecycle. Mastering the software platform across carlines will become more important as well as the ability to test the software in virtual environments. The functions will be more and more enabled by software that also has to be managed at the manufacturing line. Software will have its own lifecycle, license and inventory. The software will need to be maintained over a longer time well after end of project to enable updates in particular security compliance but also addition of functions over the vehicle lifecycle”.

“The driver and passenger experience will evolve with the introduction of the software defined vehicle, improving the in-car experience in terms of comfort and safety. Software functions will be able to be activated as requested and the vehicle becomes connected enabling safety relevant functions that can notify for example on road conditions that are not yet visible to the driver”, she concludes.

New paradigm

Belén Andrino, GMV's Director of Business Development and Marketing, states that "the concept of SDV is a new paradigm that redefines vehicles not only as means of transport but also as advanced technological platforms defined and controlled by software. The traditional design with multiple Electronic Control Units (ECUs) to control different functions, evolves towards centralised platforms that allow the integration of resources and reduce technical complexity (especially in terms of wiring) and its associated cost. In this way, the same hardware can be used for several purposes or uses and always be kept up to date through over-the-air (OTA) embedded software updates throughout its life cycle, allowing an unprecedented level of flexibility for manufacturers and users”.

Andrino argues that "this philosophy allows the same hardware to serve multiple purposes and software updates to be carried out over-the-air (OTA), giving vehicles an unprecedented degree of flexibility and customisation. It also has implications for vehicle cybersecurity as we are faced with increasingly complex software and, together with the increase in vehicle connectivity, significantly widens the attack surfaces, forcing the implementation of more advanced and specific cybersecurity mechanisms. In this sense, the VDS provides tools and capabilities to effectively combat these challenges. Moreover, this approach can also integrate solutions based on artificial intelligence (AI), machine learning and cloud computing, among others, facilitating the deployment of functionalities such as predictive maintenance or autonomous driving, thus improving safety and the driving experience".

GMV's representative underlines that "the complexity of the vehicle architecture is reduced by moving from a large number of ECUs to centralised platforms with fewer units. The incorporation of new functions implies the possibility for OEMs to offer subscription models, opening the door to new service-oriented business models. On the other hand, the supply chain is evolving as it establishes new alliances between suppliers, manufacturers, technology companies and start-ups, forcing a redefinition of the relationships between the different players. The possibility of immediate and flexible updates gives unprecedented advantages to driver and passenger experiences as they will always have up-to-date information and functionalities in many different areas, personalised and intuitive, allowing for a much more complete and positive driving experience. On the other hand, this flexibility allows the vehicle to be kept up to date over time, preventing it from quickly losing value by relying on hardware alone. This can also translate into higher customer satisfaction and increased brand loyalty.

Complexity at the system integration level

Nathanael Sladek, Vice President, Electronics Business Strategy and Product Management at Marelli, says “generally, we expect more decoupling of hardware from software to support different SDV functions. This likely will lead to a more standard definition of software interfaces like we have on our computer and smart phone today. This will accelerate vehicle software development from an application perspective but adds complexity at the system integration level. We might also see more app stores like options for the vehicle that allow personalization and enhancement of the consumer experience.

Sladek comments that “SDVs are characterized by scalability, upgradeability, and integration capabilities. Integration with artificial intelligence (AI) is not only possible but increasingly essential. AI can enhance SDV capabilities by enabling advanced driver assistance systems (ADAS), predictive maintenance, and personalized user interfaces that learn driver preferences over time”.

The representative of Marelli explains that “SDV architectures in general are reducing the number of electronic control units (ECUs) per vehicle, but they are much more complex in terms of hardware, software and highly specialized components for data processing, power distribution, and interfaces. With SDVs, we are seeing a shift in both design and manufacturing. Several Original Equipment Manufacturers (OEMs) are adopting a more build-to-print manufacturing approach where one supplier designs—an Electronic Manufacturing Service (EMS) or even the OEM itself—and another supplier produces. This approach will likely continue for new entrants in the electric vehicle sector, but for more traditional OEMs, we expect this to be applied only in specific circumstances. As for the supply chain, we currently see fewer suppliers able to keep up with the latest trends due to the greater complexity and related higher investment and speed required. We expect the supply chain to continue to consolidate to better respond to these new requirements. Marelli is responding to this evolution in both manufacturing and the supply chain. On the manufacturing side, we support a variety of business models and are developing SDV programs ranging from EMS to the more traditional Tier 1 approach. On the supply chain side, we are constantly looking for the latest technologies on the market and carefully evaluating suppliers with whom to focus our upfront advanced engineering activities”.

Sladek adds that “the adoption of SDV technology is transforming the driver and passenger experience by introducing a new level of personalization and connectivity, similar to smart phones. New and enhanced features are continuously released. End users will be able to customize their experience while the vehicle will also learn their preferences over time. AI will enable better vehicle diagnostics and support avoiding recalls and other issues”.

Decouple hardware from software

Cyril Clocher, Senior Director of the High-Performance Computing SoC Business Division at Renesas, argues that “software-defined vehicle (SDV) platforms are transforming the future of the automotive industry where user experience, personalization, connectivity and seamless device integration take the front seat. At the core of SDV is its ability to decouple hardware from software, allowing for over-the-air (OTA) updates enabling OEMs to continuously introduce new features and functionality, thus extending the life of the car. This model also allows OEMs to differentiate and bring in their own uniqueness as cars are increasingly becoming standardized. A software-first SDV approach that supports parallel hardware and software development, also referred to as a “digital twin” is key. The Renesas’ RoX SDV platform facilitates this by combining cloud-native development with a customizable simulation environment for pre/post development and deployment”.

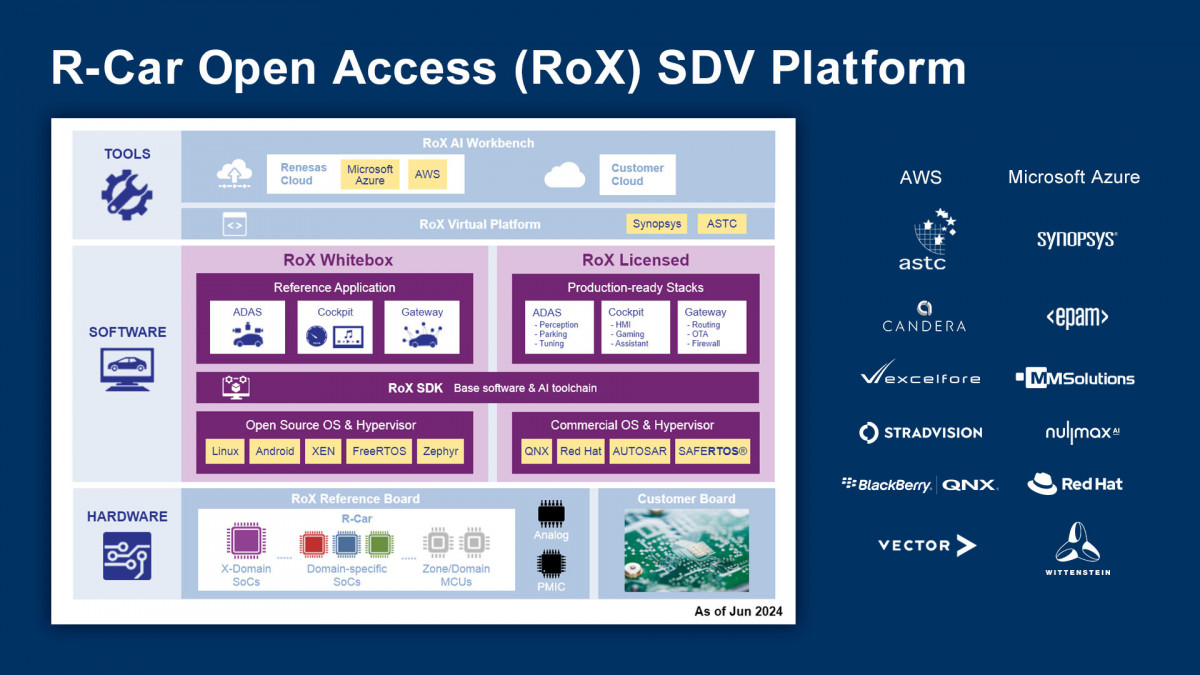

“For SDV, one key element of our strategy is Renesas’s R-Car Open Access (RoX) platform. Built on open-source with pre-integrated ecosystem solutions, it accelerates time to market and maximizes reuse of development assets. In parallel, we also focus on delivering high-performance & optimized MLOPs with integrated tools platform and end-to-end AI toolchain including simulators, AI compiler & workbench combined with cloud infrastructure to support large scale testing. With RoX SW first approach, we’re delivering the SDK & in-house system proof of concept to enhance validation by testing system integration & KPIs. It maximizes reuse of development assets and accelerate customer evaluation It also provides our customers with the first level of system validation with testing of complex central ECU system integration and KPIs”, he says.

For Clocher “the SDV architecture is highly software and data centric versus the traditional hardware-oriented architecture. Software architecture allows for ease of development with shorter time to market, personalization and customization, and upgradeability via OTA updates. The data driven approach facilitates collecting, analyzing and processing vast amounts of data from sensors, controllers, etc. allowing AI capability for advanced autonomy and in-cabin infotainment. SDV also drives centralization with simplified centralized compute architecture compare to the complexity of multiple control units in a distributed architecture”.

Renesas has a long history with compute and safety-oriented products for automotive systems and “we’re very excited to help solve unique auto industry challenges. What sets Renesas apart especially with latest R-Car X5 investment is the delivery of a flexible platform that can be customized – and with software upgradability– to meet the requirements of any use cases ranging from specific domain integration for ADAS or cockpit and infotainment ECUs to cross-domain compute (aka fusion) in vehicles ranging from very high end to entry level. Renesas’ development platform, Renesas Open Access Platform (RoX) is a truly unique open SDV platform that integrates all essential hardware, operating systems (OS), software and tools needed for automotive developers to rapidly develop next-generation vehicles with secure and continuous software updates”, Cyril Clocher comments.

“The SDV shift is driving what you can refer to as the ‘Smartphonification’ of cars. With this the cars become an extension of users’ smartphones enabling personalized vehicle experiences. This provides them with a seamless transition from their digital life outside the vehicle to the in-vehicle environment. The continuous upgrades of new features and functionality via OTA, enabling and disabling features and integration with software as service (SaaS) open up a world of possibilities, all thanks to the SDV architecture. AI will be the cornerstone of enhanced and personalized experiences in the cockpit. Combining the digital lives of drivers and passengers with in-cabin sensing and perception around the car will enable endless experiences from smart navigation and driving to concierge services or personalized entertainment to name a few”, he concludes.

Dynamic plataform

John Heinlein, CMO at Sonatus, thinks “software-defined vehicles (SDVs) are fundamentally changing how cars are designed, built, and experienced. Instead of designing a vehicle with fixed capabilities, automakers can now treat the car as a dynamic platform that improves over time. That shift opens up new possibilities during development: instead of locking in features before production, engineers can focus on flexibility, like releasing software updates, adding features, or tuning performance after the car is on the road. Over-the-air (OTA) updates are a key enabler: with the right software foundation, OEMs can fix bugs, improve systems over time, or even introduce entirely new services remotely. That’s a win for drivers, who get a car that improves, and a win for automakers, who can continue to innovate and monetize throughout the vehicle’s lifecycle and improve brand loyalty. According to new data from Sonatus and Wards Intelligence, 78% of automotive professionals expect broader OTA use by 2026-2027”.

Heinlein affirms that “at its core, SDV software is built to be modular, adaptable, and cloud-connected. It works across different hardware platforms, which allows OEMs to deploy new features quickly and efficiently. AI fits in naturally. While people often think of AI in terms of self-driving, there’s huge value in using it for everyday tasks like diagnostics, maintenance alerts, and personalized cabin settings. Vehicles today generate massive amounts of data (up to 25 GB per hour, says S&P), which creates both a challenge and an opportunity. AI is increasingly essential to make sense of that data and deliver real-time value for drivers and manufacturers alike. According to the 2025 State of Software-Defined Vehicles report, the most promising AI use cases include predictive maintenance, dynamic performance tuning, and smart comfort features. For example, Sonatus’s AI Technician Builder lets manufacturers create digital assistants that can identify issues, offer tailored advice, and help drivers get the right service at the right time”.

The representative of Sonatus says “SDVs can streamline manufacturing by consolidating hardware into fewer compute modules in the car, enabling flexible architectures that also reduce wiring complexity and cost. On the supply chain side, SDVs enable smarter inventory planning and predictive maintenance, reducing downtime and service costs. With real-time data and remote diagnostics, OEMs and fleet operators can optimize operations and adapt more quickly to market demands”.

“SDVs turn vehicles into adaptive digital platforms. With AI-powered assistants, intuitive voice interfaces, and real-time updates, drivers enjoy smarter diagnostics and more personalized in-cabin features. For example, vehicle behavior can adapt to driver preferences or usage patterns. Real-time analytics also enable early maintenance alerts, enhancing safety and reducing disruptions. Ultimately, SDVs elevate the driving experience from static and mechanical to intelligent and continuously improving”, he concludes.

Las ventas de vehículos electrificados (eléctricos e híbridos enchufables, comprendiendo turismos, cuadriciclos, vehículos comerciales e industriales y autobuses) mantienen un ritmo ascendente y logran un aumento del 152,5% en julio, con 22.898 unidades, que supone el 19,28% del mercado total.

El mercado del automóvil sigue mostrando fortaleza en 2025. En julio, las ventas de turismos registraron un aumento del 17,1%, alcanzando las 98.337 unidades, muy cerca de la simbólica barrera de las 100.000 entregas.

El Grupo Volkswagen incorpora Microsoft Copilot en Codebeamer, la plataforma de gestión del ciclo de vida de las aplicaciones (ALM, por sus siglas en inglés) de PTC, partner de Microsoft, para afrontar la creciente complejidad del desarrollo de vehículos.

Iveco Group, fabricante europeo en vehículos comerciales y movilidad, y el grupo indio Tata Motors, han anunciado que han alcanzado un acuerdo, por el que la compañía asiática adquiere ala firma italiana, para crear un grupo de vehículos comerciales con el alcance, la cartera de productos y la capacidad industrial necesarios para convertirse en líder mundial

La sostenibilidad es un tema cada vez con mayor importancia en la cultura empresarial. Los criterios ESG (Environment, Social and Governance), vertebran gran parte de las acciones de las compañías. Ante este contexto hemos hablado con Carolina López, gerente de Comunicación y Sostenibilidad de SERNAUTO.