AutoForm unveils its solution for BiW Assembly

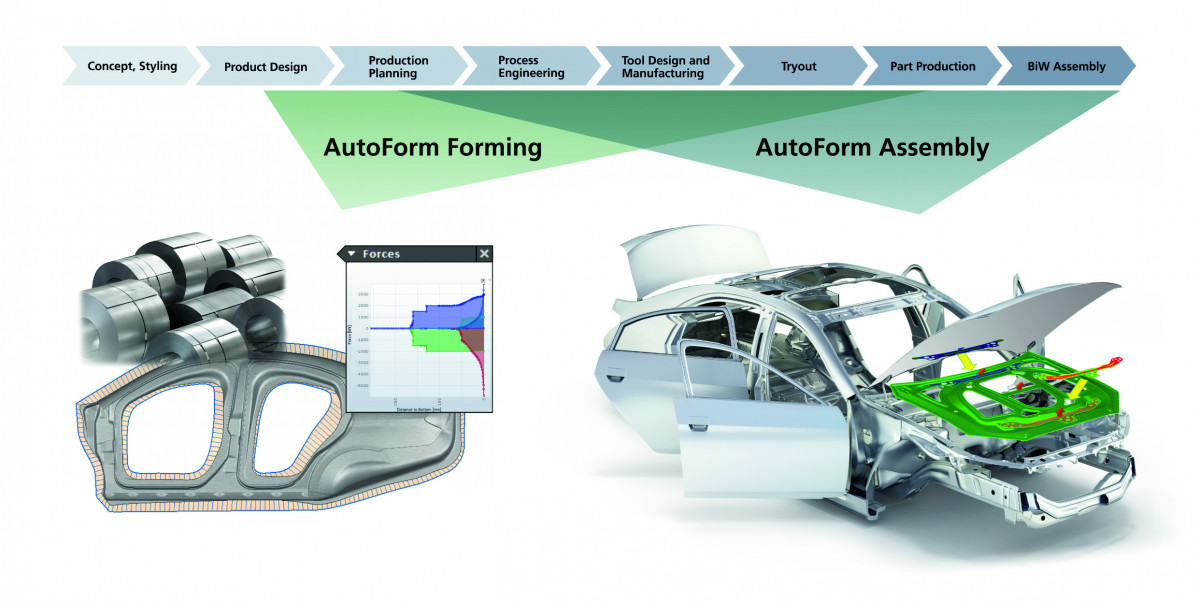

AutoForm Engineering, a global supplier of software solutions for stamping and BiW assembly processes, has unveiled its latest software solution AutoForm Assembly. This solution covers the BiW assembly process chain, combining all of the critical aspects of assembling parts. AutoForm Assembly enables users to address complex issues in the BiW assembly process before they can arise in production and expand digitalization. AutoForm’s solution for BiW assembly supports the entire BiW process chain, which covers early feasibility, process engineering and BiW production.

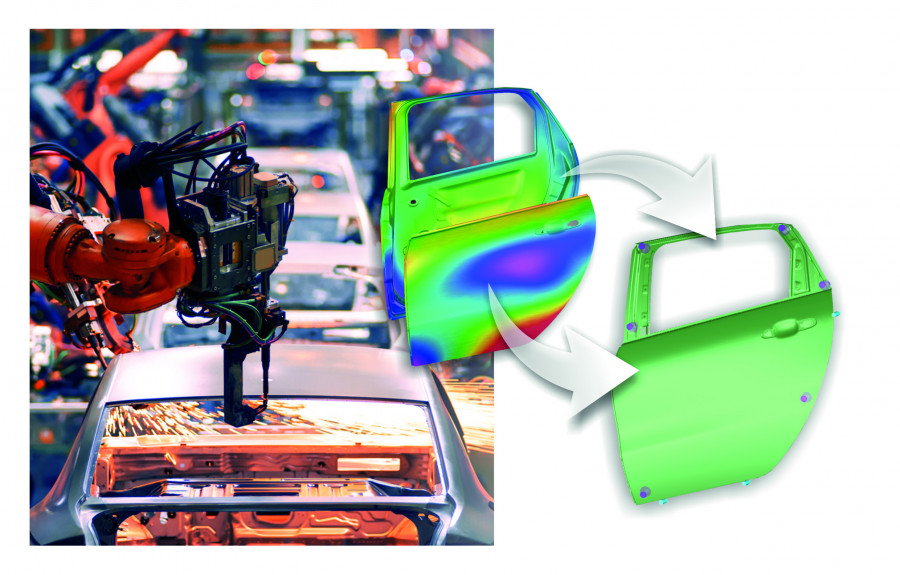

By implementing AutoForm software for the BiW assembly process, users can gain deep insight into the car body manufacturing process, quickly evaluate alternative part and assembly process designs, identify the causes of dimensional deviations and undertake effective countermeasures. The combination of AutoForm Forming and Assembly solutions covers the stamping and BiW assembly processes. With unique AutoForm Assembly capabilities, users can virtually set up the entire assembly process, including joining and hemming technologies. They can make process modifications easily by taking into consideration different part insertion orders, changes to pilot and clamping positions, and different sequencing of the joins.

AutoForm Forming and Assembly solutions cover stamping and BiW assembly processes.

With this software, they can achieve higher product maturity earlier in the development process and reduce the number of product modifications later in tryout and manufacturing. The software allows them to save on costs for tooling and equipment modifications as well as to reach higher process maturity and greater robustness at tryout and the start of the production.

Dr. Markus Thomma, CMO of the AutoForm Group, stated: “We are glad that we can now offer a unique and first to market software solution to users in the BiW area. For many years, AutoForm Forming has been the software of choice for part makers, tools shops and engineering service providers worldwide. Now, with AutoForm Assembly, we are expanding the covered manufacturing processes and offering a state-of-the-art software solution to customers in the field of BiW assembly. With AutoForm Assembly, they can achieve tangible benefits in their daily work in terms of both cost and lead time savings.”

A requerimiento de AutoRevista sobre la imposición de aranceles del 30% a vehículos y componentes de la Unión Europea por parte de la Administración Trump, desde CLEPA señalan que "instamos encarecidamente a la UE a que impulse una exención para las piezas de automóviles en cualquier acuerdo.

La Asociación Española de Renting de Vehículos acaba de presentar su informe anual, y con él cifras más que optimistas para el segmento. Tanto es así que el parque de vehículos en renting ha crecido el 6,11% durante el primer semestre de este 2025 (una cifra levemente superior a la prevista por la asociación, el 6%), lo que implica que este asciende a 984.354 unidades totales.

Nissan ha construido un nuevo centro de reacondicionamiento de vehículos en la Planta de Nissan Ávila, diseñado para ofrecer a los clientes la experiencia de reestrenar un coche, gracias a un proceso altamente especializado y con los estándares de calidad Nissan.

PowerCo Battery Spain (PowerCo) y el ITE (Centro Tecnológico de la Energía) han establecido un acuerdo de colaboración con el objetivo de incrementar las capacidades formativas sobre esta industria pionera en España.

La filial española de Dacia ha designado a un nuevo Comité de Dirección con el propósito de continuar creciendo en 2025, después de lograr los mejores resultados de su historia en el primer semestre del año con un 9,6% de la cuota del mercado a particulares.