A technology that expands its possibilities in the automotive industry

We have the insights of five specialists who analyze the future of additive manufacturing in the automotive industry. New cost savings, suitability for electrification, synergies with other sectors... additive manufacturing continues to forge new paths in the automotive industry.

Lea esta noticia en castellano

Article published in AutoRevista 2.402

Águeda Peña, Marketing Manager for Iberia at 3DZ, stated, "Additive manufacturing has revolutionized the automotive sector, especially in the development and validation phase of new products. In this sense, 3DZ, the leading distributor of 3D technologies in Europe, is seeing how its automotive customers are increasingly using 3D printing to accelerate functional prototyping, eliminating tooling costs and drastically reducing validation times. In pre-series and short-run production, technologies such as pellet extrusion make it possible to manufacture final parts in technical, durable materials at competitive costs, even making on-demand manufacturing viable.

Regarding electrification, as a determining trend in the automotive and mobility sectors, the 3DZ representative believes that "it is driving demand for lighter, more compact, and more efficient components. 3D printing allows for the optimization of the design of structural parts, heat pipes, and customized elements, contributing to the performance of electric vehicles. Furthermore, additive manufacturing favors more sustainable production models: it reduces material waste, enables the use of recycled plastics, and shortens the logistics chain through localized production. At 3DZ, we're detecting growing interest in technologies that facilitate these goals."

Regarding applications that can be extrapolated to the automotive world from other sectors where additive manufacturing is more widely used, Águeda Peña points out that "the medical sector, for example, has developed complex geometries such as lattice structures, ideal for lightweighting components without compromising strength. These solutions are already being applied in supports, interior parts, and safety elements in the automotive industry." Advances in the aerospace sector are also being leveraged, such as certified materials and topology optimization techniques, which improve performance and functionality."

In conclusion, the Marketing Manager for Iberia states that "the trend is clear: automation, speed, and control. New technologies such as PSLA (rapid large-format stereolithography) allow for the production of multiple parts with high resolution and speed. Added to this is an increasingly connected ecosystem, where software, hardware, and post-processing work in an integrated manner. At 3DZ, we anticipate that 3D printing will move from being a validation tool to becoming a common production technology in the automotive industry."

More robust quality standards

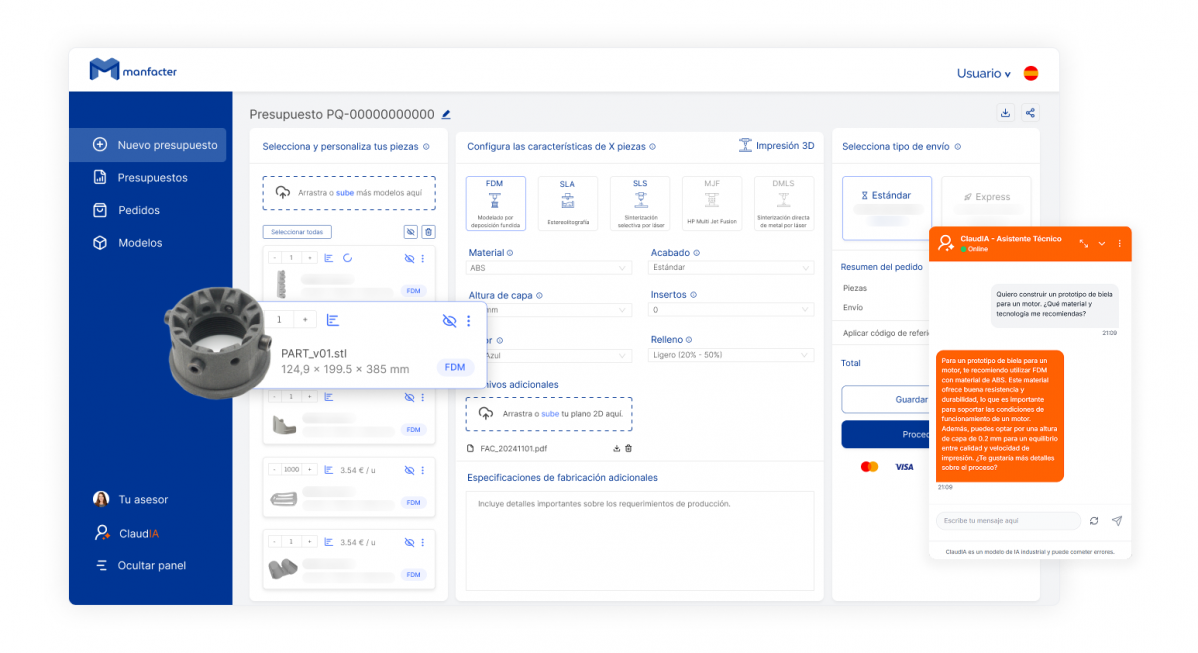

At Manfacter, a platform specializing in digital solutions for advanced manufacturing, Alberto López de la Torre, CEO, believes that “additive manufacturing is undergoing a solid evolution in the automotive sector, moving from rapid prototyping, its traditional application, to increasingly being integrated into pre-series and short-run production, especially in customized components, tooling parts, electronic housings, and lightweight geometries. This progress has been fueled by cost reductions, improvements in technical materials (polymers and metals), and the emergence of more robust quality standards.”

For López de la Torre, “the transition toward electric and sustainable mobility offers a new field of expansion for additive manufacturing. The ability to design lighter parts, key to energy efficiency, and the possibility of manufacturing on demand, reducing inventories and logistics emissions, make this technology a strategic ally. Furthermore, the customization it enables is essential in niches such as modular platforms or urban vehicles.”

From sectors such as aeronautics, defense, and medicine, where additive manufacturing is already widely adopted, the Manfacter representative believes that "the automotive sector can extrapolate good practices in traceability, material qualification, and the use of digital twins for quality control. At Manfacter, for example, we already work with automotive manufacturers that apply mixed manufacturing flows (traditional and additive) inspired by these sectors, with very positive results in terms of time and costs."

Among the most relevant trends, Alberto López de la Torre highlights "process automation, the use of artificial intelligence to optimize geometries and estimate production viability, as well as the growth of platforms that connect demand and manufacturing capacity in real time, such as the one we offer at Manfacter. We believe that additive manufacturing will continue to evolve as a complementary, hybrid, and strategic technology in the industrial ecosystem of the future.”

Strategic role

According to Germán Escalante, teaching leader at the School of Computer Science and Communications at Master D, “additive manufacturing is taking on a strategic role in the automotive industry, not only as a rapid prototyping tool, where it has already amply demonstrated its value, but also in pre-series production, short runs, and even in certain long-run applications. Design flexibility, reduced development times, and the ability to produce complex geometries that would be unfeasible with traditional methods are transforming design and manufacturing processes. Leading companies in the sector are already integrating technologies such as selective laser sintering and electron beam melting into their production lines for structural and custom components.”

The move toward electrification and sustainability reinforces this trend, according to Escalante. “Electric vehicles require lighter and more customized components, which fits perfectly with the capabilities of additive manufacturing. Furthermore, the ability to manufacture parts on demand, with less material waste and closer to the assembly point, contributes to reducing the carbon footprint of the production process. The integration of recycled or more sustainable materials is also more viable in additive manufacturing environments, reinforcing its value within circular economy strategies.”

The Master D representative points out that “additive manufacturing has matured significantly in sectors such as aerospace, medicine, and energy, where it is already used to produce critical parts with very demanding quality standards. These experiences are being adapted to the automotive world, creating very valuable synergies.” For example, knowledge in generative design and advanced materials from the aeronautical sector is accelerating the development of more efficient and lightweight automotive components.”

Regarding innovation, Germán Escalante points out that “the current trend focuses on the development of new metal alloys, reinforced polymers, and composite materials specifically for 3D printing, as well as improving the speed and precision of printers. Furthermore, post-process automation and integration with digital design and engineering tools are bringing additive manufacturing closer to a truly industrial environment. All of this suggests that additive manufacturing will move from being a complementary tool to becoming a key pillar of the automotive industry of the future.”

However, despite all this, the Master 3D representative believes that “a significant training gap persists, limiting its large-scale deployment in the sector.”

Carbon Footprint Reduction

Alejandro Nieto, Product Engineer at Meltio, states that "the production lines of automotive manufacturers around the world are increasingly relying on metal additive manufacturing technology, not only for part design and prototypes but also for final series parts. In the case of our technology developed by Meltio—which is based on so-called DED (Digital Digital Electrode Design) because an energy source, in this case lasers, melts a wire of metallic material like a weld—these types of companies in the automotive sector require our technology for repair and part manufacturing. Our technology, with a patented Meltio head, allows for 3D printing of parts in aluminum, copper, titanium, stainless steel, copper, nickel, among other materials."

Regarding the combination of electrification and sustainability, the Meltio representative maintains that "these trends, along with rational use and a reduced carbon footprint, are two characteristics of the metal additive manufacturing technology we develop at Meltio. Our technology does not generate waste from the material used for 3D printing parts because, by using solder wire instead of powder, like other technologies, our 3D printers and automotive customers use only the filament they need. This helps them integrate our printers into their production lines and into their workshops for repairing and creating metal parts for their vehicle models, helping to reduce their carbon footprints." Nieto comments that "with our technology, injection molds and cooling molds can be manufactured." Our current portfolio of metal additive manufacturing solutions has been developed for more than three years after undergoing rigorous quality, testing, and validation processes before reaching the industrial market. All our systems share the same patented process based on LMD (a type of directed energy deposition (DED) process that creates the metal part layer by layer using the technique of melting the metal wire through laser welding) capable of manufacturing parts using basic welding wire.

Looking to the coming years, the Meltio representative comments that "we are seeing that metal 3D printing technology is booming and in strong demand from industries around the world. At Meltio, we offer our metal additive manufacturing solutions that can work directly on a production line 24/7 with high levels of efficiency in the 3D production of parts in materials in high demand by industries such as stainless steel, titanium, nickel, Inconel, aluminum, titanium, among many others." The main challenge remains for industries around the world to continue validating and trusting additive manufacturing as a reliable manufacturing method and to continue incorporating it into their production methods for mass production.”

Devastating Progress

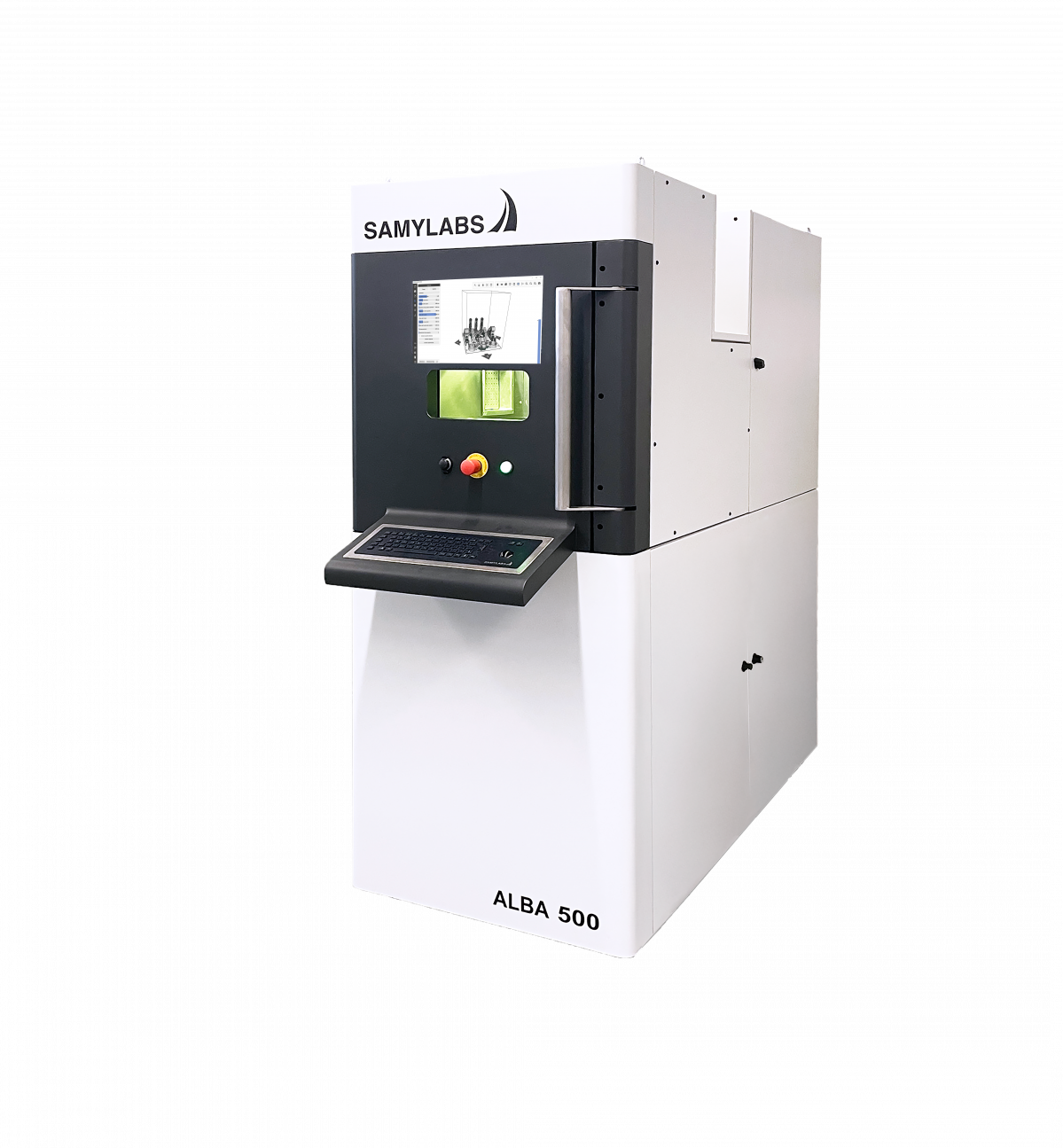

Regarding the progression of additive manufacturing in the automotive industry, Jon Martínez, CEO of Samylabs, believes that "from the perspective of prototyping and testing new components, the progress is simply devastating. Most of the €6 billion that the global automotive industry already allocates to AM continues to be concentrated on functional prototyping: engine casings, intake manifolds, or assembly tools that previously required weeks are printed in 24-48 hours, assembled the next day, and redesigned in the same sprint. Once the design is validated, OEMs require batches for crash tests, NVH validation, or marketing clinics. Here, AM avoids investing hundreds of thousands of euros in tooling. These pre-series parts travel directly to the test bench without molds, reducing delivery time by 60%. From the perspective of short-run production, from 1,000 to 20,000 units, Premium platforms and high-end electrified sports cars are adopting AM to reduce weight and differentiate themselves, but the manufacturing price of these components still needs to be justified as a luxury item”.

Regarding electrification, the CEO of SamyLabs argues that "electric motors and inverters require compact housings with internal lattice structures to cool the oil or dielectric. LPBF technology allows printing parts with internal channels and conduits that cannot be manufactured with other technologies and are ideal for these types of applications. At this point, we have heat exchangers, cold plates for battery packs, or hairpin stators in aluminum and copper alloys (CuCrZr), which are excellent examples of new applications linked to electrification. From a sustainability perspective, a saving of 1kg in an electric vehicle avoids approximately 25 kg of CO₂ over its lifecycle. Generative LPBF topologies enable reductions of 20-60% in suspension mounts and electronic brackets. Some studies confirm that, starting at 20,000 km, the net footprint is already favorable for AM compared to casting and machining. At the same time, material waste due to chip removal is reduced from 80-90% to 5-10% during the manufacturing process. A success story we are currently working on at SAMYLABS, and for which we already have several machines installed, is the manufacturing of molds for thermoformed tubes using additive manufacturing. Vehicles require numerous tubes that must have a specific shape. Shaping these tubes requires the manufacture of complex molds that are very difficult to manufacture using traditional techniques. Additive manufacturing simplifies and accelerates the manufacturing of these molds”,

Regarding compatibility with other sectors, Martínez explains that "LPBF technology currently faces a major challenge, which consists of identifying new application use cases. Those accustomed to traditional manufacturing methods sometimes find it difficult to imagine a new way of manufacturing, and it is risky and costly to demonstrate that this new method is more efficient and economical. At Samylabs, we have developed a short, four-question questionnaire that allows us to identify, regardless of the sector, whether a part can be manufactured with LPBF technology in a significantly more competitive manner than with conventional methods. Our SamyStudio software also allows for quoting printing jobs and a detailed comparison of traditional production costs versus additive manufacturing."

For Jon Martínez, regarding the coming years, "the next big revolution will come from generative design and AI. In 2024, the use of artificial intelligence through chatbots will become standard, and we are currently working with reasoners such as ChatGPT or 3. By 2026, we'll likely see autonomous agents controlling many of our systems, and by 2027, innovative intelligence will become a reality, starting to design for us. When this intelligence designs on a massive scale, it will do so in surprising ways, with more efficient and resilient generative topologies, which in many cases can only be manufactured with AM technology. At this point, the growth and demand for this technology will skyrocket, and at Samylabs, we hope to be well positioned to meet this growth”.

AutoRevista refleja varios testimonios de empresas que participaron de una u otra forma en la reciente edición de los Mobility and Industry Suppliers Meetings), organizados por el CAAR, en colaboración con otros siete clústeres, el 22 de mayo en el Mobility City de Zaragoza.

Según datos de SERNAUTO, los proveedores de automoción facturaron 41.238 millones de euros en 2024, lo que supone un leve descenso del 0,7% respecto a 2023. De este modo, el sector se mantiene por encima del umbral de los 40.000 millones, alcanzado por primera vez en 2022. Una información de Irene Díaz.

Más de 50 profesionales de la industria de automoción y movilidad se han reunido en Vigo en una jornada organizada por CEAGA para analizar y compartir estrategias y mejores prácticas para optimizar, automatizar y digitalizar los procesos de logística interna de las empresas del ecosistema de automoción y movilidad de Galicia.

Las Asociaciones Europeas de la Industria del Automóvil, ACEA, CLEPA y EUCAR han acogido con satisfacción los anuncios de la Comisión Europea en el Plan de Acción Industrial para el sector europeo del automóvil con el fin de reforzar su competitividad.

Con motivo de la edición 2025 de Viva Technology, Software République se ha unido a tres unidades de bomberos para desarrollar «vision 4rescue», un conjunto de soluciones tecnológicas interconectadas destinadas a mejorar la eficacia y la coordinación de los servicios de emergencia.