Key allies in the digitalization and sustainability of Stellantis Zaragoza

Lea este artículo en castellano

Artículo publicado en AutoRevista 2.401

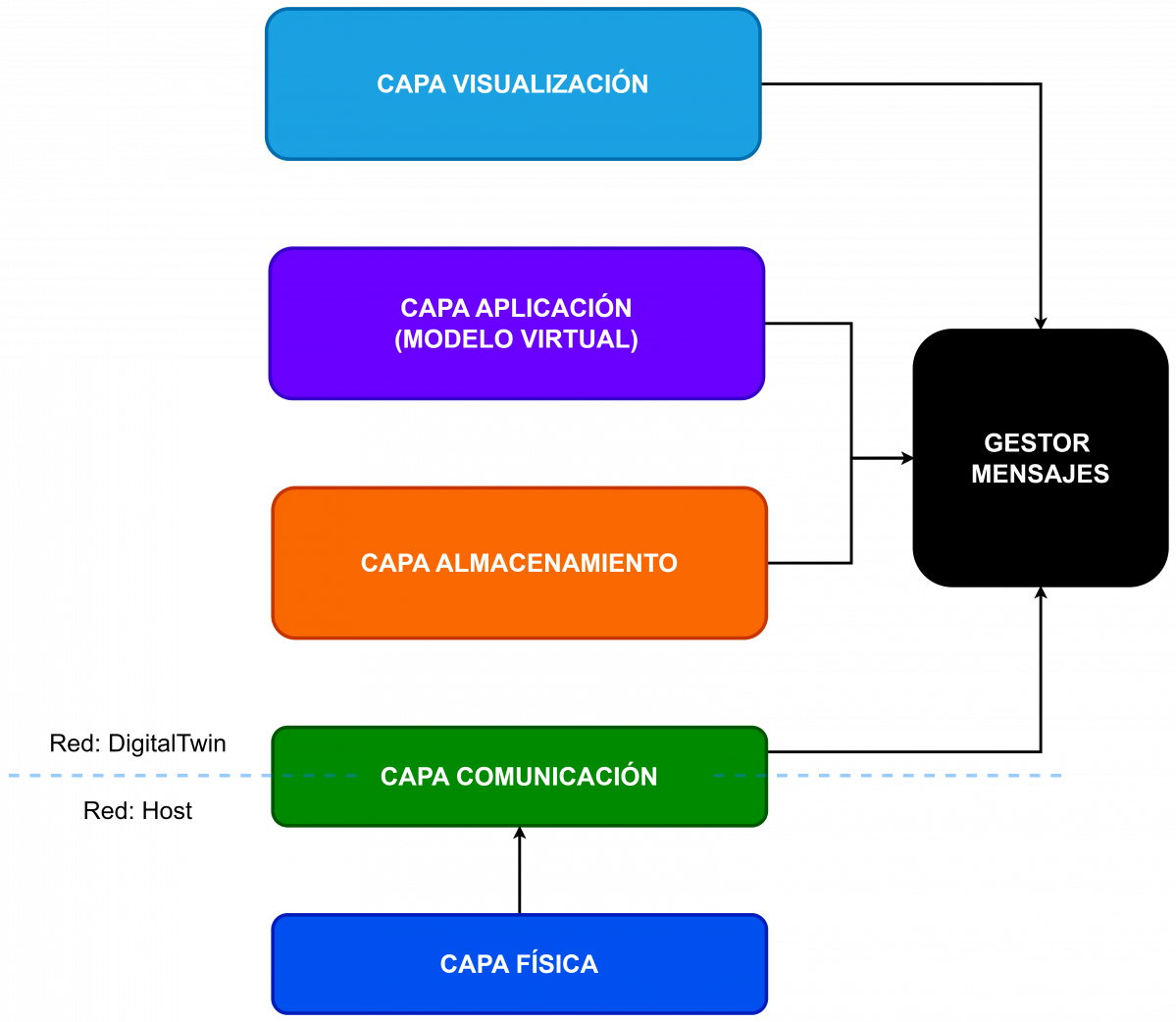

“For years, at Electroingenium, we have actively contributed to improving operational efficiency and sustainability at the Stellantis Zaragoza plant, combining our expertise in industrial automation with emerging Industry 4.0 technologies, such as Edge Computing, digital twins, and virtual commissioning,” explains Lucía Royo, the company's Innovation Manager. One of the most notable projects is IA4Q (CDTI Transmissions), aimed at improving quality through artificial intelligence and the digital twin. “This project is enabling us to optimize defect detection in critical processes, improving traceability and reducing errors. Furthermore, at the automation level, the introduction of variable frequency drives in industrial systems has significantly reduced energy consumption, reinforcing our commitment to sustainability,” explains Royo.

“Our collaboration with Stellantis began several years ago through various automation projects within the factory, consolidating a relationship based on trust, honesty, and results. Participation in the CDTI Transmissions project has been key to taking this a step further: in it, we led research line 3, based on Edge Computing and the Digital Twin, which has opened up new possibilities for predictive analysis and the simulation of what-if scenarios. This experience has laid the foundation for potential collaborations with other plants in the group, both in Spain and internationally,” notes the company representative.

Among the most significant advances is the implementation of the battery workshop case, focused on automatic fault detection in the assembly of electric vehicle batteries, using artificial vision and machine learning algorithms, all integrated into a modular Edge environment, in collaboration with ATRIA (vision) and ITAINNOVA (ML algorithms). "Furthermore, in another case, a virtual replica of the quality process has been developed, an essential tool for evaluating improvements without affecting production."

“Our next goals focus on scaling this architecture, integrating new types of sensors—such as ultrasound or hyperspectral cameras—and running models on CPUs and GPUs within the Edge, thus expanding the system's responsiveness. We particularly value cooperation with other companies, such as ATRIA Innovation, and technology centers like ITAINNOVA, as it allows us to benefit from shared knowledge, enrich our solutions with complementary perspectives, and form multidisciplinary teams capable of tackling complex challenges. This type of collaboration boosts the competitiveness of technology SMEs and strengthens the local industrial ecosystem with an innovative and sustainable approach,” concludes Lucía Royo.

Hybrid Wind-Solar Project

At the Stallantis Zaragoza plant, Prosolia has developed a customized hybrid wind-solar project "adapted to its needs. The project, which will be developed in different phases, will produce clean energy with a capacity of up to 30.8 MW from solar power and 27.6 MW from wind power. This will allow 80% of the car factory's electricity needs to be covered with renewable sources," explain company sources.

In this way, the Figueruelas factory not only advances its decarbonization goals by avoiding the emission of approximately 14,800 tons of CO2 per year, but also boosts its competitiveness. For example, consumption occurs in the same location where the energy is generated, avoiding large transportation infrastructure and providing greater energy independence.

The collaboration between Stellantis and Prosolia Energy began in 2020 with an initial contract for 14 MW in Zaragoza, which has grown to a hybrid wind-solar self-consumption project. Since then, our collaboration has expanded to Spain and other countries. “We currently also operate the largest rooftop self-consumption system in Spain, with 18.3 MW at its Vigo plant. We recently expanded our partnership to develop new renewable facilities in France and Germany, which will allow us to supply clean energy to its plants through power purchase agreements (PPAs). In total, we have an international self-consumption portfolio of nearly 200 MW, allowing us to support Stellantis in its strategic plan to achieve carbon neutrality by 2038,” Prosolia sources indicate.

The same sources point out that “with the upcoming projects we will develop, five in France and three in Germany, we are consolidating our position as Stellantis' strategic partner for the energy decarbonization of its factories in Europe. We are confident that this new collaboration will allow us to face new challenges together internationally. These types of collaborations are essential to driving the transformation of the energy model toward a decarbonized one, fostering innovation, and positioning the industrial sector at the forefront of a growing global market.” As Independent Power Producers (IPP), we are committed to innovation to combine different types of technologies and develop more competitive and efficient hybrid projects tailored to the needs of each client.”

A poco más de tres meses de una edición histórica como será el 50 aniversario de Equip Auto, Aurélie Jouve, directora del Salón, nos avanza todos los detalles de la cita del 14 al 18 de octubre en Paris Expo Port de Versailles.

Carta del director editorial Nº 2.403 de AutoRevista

El sector español de proveedores de automoción finalizó 2024 con unas exportaciones valoradas en 25.065 millones de euros, lo que supone una leve caída del 0,5% respecto al récord alcanzado en 2023.

![X1310 ETECH HR18 DB45 OverviewG ORANGE[31] X1310 ETECH HR18 DB45 OverviewG ORANGE[31]](/images/showid2/7434115?w=981&zc=4&zc=1&w=280&h=209)

HORSE Technologies ha desarrollado su nueva unidad motriz híbrida integrada, la HR18 HEV. Se trata de la primera unidad motriz completa diseñada, desarrollada y producida bajo la marca HORSE Powertrain, y se ha desarrollado en los centros de I+D de Rumanía y España.

La fabricación de vehículos eléctricos de batería (BEV) en el Reino Unido superará con creces las previsiones realizadas para la fabricación mundial y europea, y los fabricantes de automóviles británicos alcanzarán una producción casi total de vehículos eléctricos de batería en 2035, según un informe de Advanced Propulsion Centre UK (APC).