Hexagon sets out its vision for today's digital models in manufacturing

By creating accurate digital models of the manufacturing process, OEMs can also simulate production before physical manufacturing begins. Jordi Planell, Sales Manager of Hexagon Iberia, comments that "this reduces the necessity for physical prototypes and enables manufacturers to identify and address issues earlier in the value chain. Virtual assembly is a new approach that is being embraced by the automotive industry as they scale up electric vehicle (EV) production.

"Virtual assembly serves as a powerful tool within the realm of vehicle manufacturing by seamlessly integrating the physical aspects of production, including metrology with the virtual realm of engineering design, creating a single digital twin. As soon as the first prototype parts are made, or sourced from suppliers, these can be integrated into the virtual prototype further improving the accuracy of the digital twin. Here metrology plays a vital role in acquiring the data and processing it so that the user can easily reconcile with the “predicted” dimensions, surfaces, tolerances. Technologies such as structured light scanning, and 3D laser line scanning create detailed point clouds with key feature measurements and detailed surfaces that could have required multiple devices and technologies in the past".

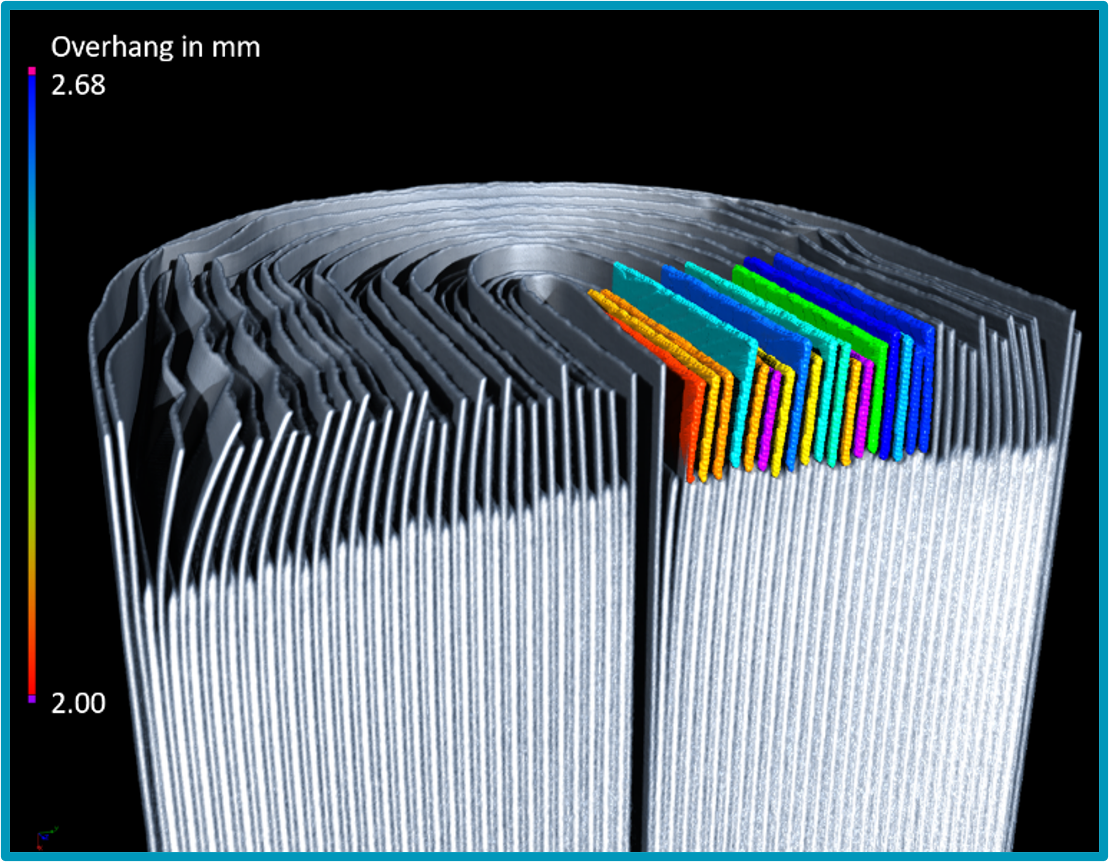

Planell says "battery quality and integrity are of particular concern for all battery manufacturers because they directly affect safety—no more so than in the case of passenger-carrying EVs. Ensuring battery quality as production volumes increase presents a challenge that can result in huge financial losses if not approached with due consideration. If you’re making several cells a minute, a 10% defect rate can equate to several hundred thousand dollars in waste a day. Unlike simple mechanical parts, the manufacturing process of EV batteries has an impact on their final chemical and mechanical structure as well as the composition of the battery. However, opening finished batteries for testing is impractical since it makes them unusable. To overcome these issues, non-destructive testing (NDT) techniques are an efficient solution to minimise product waste, reduce costs, and improve battery reliability and safety. One increasingly applied NDT technology is industrial computed tomography (CT), which has proven to be a powerful ally for battery quality inspection and root-cause analysis. Only a few years ago, rudimentary 2D inspection of batteries was common but only called upon to validate and add insight into a known problem. Today, advanced analysis software such as Hexagon’s VGSTUDIO MAX has taken a pivotal role in integrating, cleaning, processing, and visualising 3D datasets".

In 2024, European automotive OEM’s continue to adopt innovative production technology, which includes optical 3D metrology to improve quality, boost productivity, and reduce costs. "For example, optical 3D metrology uses light to measure physical properties such as distances, dimensions, and temperatures, which unlike conventional coordinate measuring machines (CMMs), which capture a few hundred 3D points of a component, 3D optical metrology measurements include millions of points. This advancement allows optical metrology tools to create complete digital twins that can be preserved for later examination or predictive maintenance. Non-contact 3D scanners use the latest 3D imaging and laser triangulation to measure a wide range of complex EV components, including batteries, electric motors, power electronics, fuel cells, and gears, with unparalleled accuracy", indicates Hexagon's expert.

"We recently announced Hexagon’s 2024 Advanced Manufacturing Report, which revealed that 88% of respondents believe improved communication is key to higher product quality. Industry practices highlight the importance of two critical feedback loops in manufacturing. The first involves applying metrology and quality assurance (QA) data to real- or near-real-time volume manufacturing operations, which is crucial for continuous improvement. This approach is particularly beneficial when maturing new processes before scaling up. The second loop focuses on product improvement, where lessons learned through analysis of metrology and QA data, are used to enhance future product designs for tier 1 manufacturers".

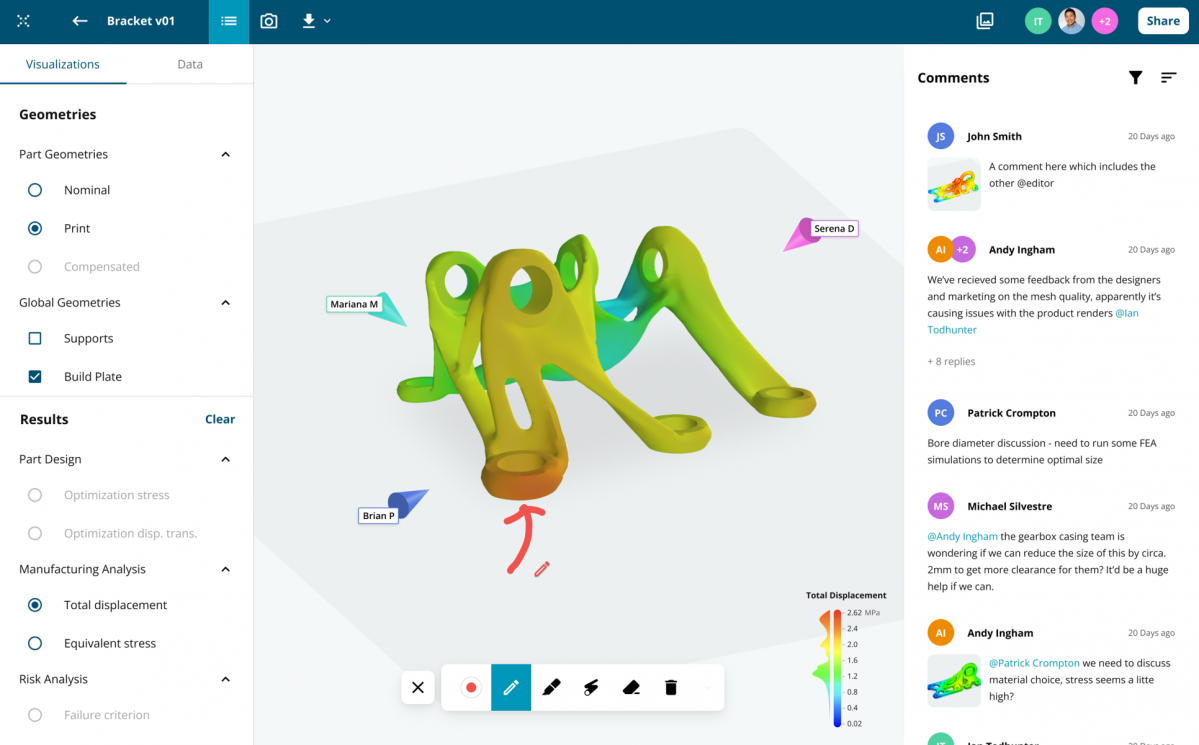

"With our new automated robotic inspection system - PRESTO, automotive manufacturers can reduce quality inspection times, increase efficiency, and streamline workflows. The systems enable OEMs to meet the challenges of manufacturing EV’s by increasing measurement capacity, and thus reducing time to market by using end-to-end inspection in a turnkey package which is powered by the best 3D-laser scanning technologies in the industry, ensuring that any surface, even highly reflective materials, can be easily inspected. The automated robotic inspection system also aligns with Hexagon’s digital reality platform, Nexus that applies the latest cloud technologies to unblock innovation bottlenecks, enabling global teams to collaborate in real-time across the product lifecycle – from design and engineering to production, and thereby making better-informed decisions".

"On our Nexus platform, OEM’s can access Metrology Reporting, a Nexus App, that connects Hexagon and third-party metrology data sources from different locations in Nexus’ secure cloud environment so that automotive OEM’s of all sizes as well as suppliers can interact and collaborate via a 3-D Whiteboard to enable them to addresses previously untapped quality control data from their equipment to spot trends and identify tolerance issues".

New ways of designing and manufacturing

OEM’s will have to adapt and manage new production processes to create new parts that are integral to the manufacture of electric vehicles – from batteries to powertrains. To meet this end, flexibility and digitisation are the two key words that will define the transformation of car production, as manufacturers embrace new ways of designing and manufacturing vehicles.

"To enhance their products and processes, automotive manufacturers must embrace the use of design software in conjunction with modelling and simulation software to overcome the challenges of complex designs and shorter development cycles. AI and machine learning (ML) enables automotive manufacturers to move from the traditional paradigm to a brand new one, where CAE simulation is used for design of experiments (DOEs) to feed AI models with shared data that will then be reused for much faster runs, improving productivity and allowing for a greater optimisation of products".

"Material behaviour modeling is also helping designers determine if they can replace established automotive-grade materials such as polyamides with new plastics from automotive material suppliers. Some new materials are made from recycled plastics, and they are themselves recyclable offering up to 60% lifecycle reduction in carbon emissions as aswell as reduced water and energy use. Without simulation mechanical engineers can’t assess their suitability in real-world scenarios or over the life of the vehicle so material models such as those we’ve developed with Sumika using our Digimat software are a crucial “missing link” for sustainable development. Here, both destructive testing of the newly engineered parts and non-destructive testing and evaluation of the material structure with CT scan analysis play an important role validating performance and quality".

"In the past, increasing efficiency in manufacturing meant bigger and faster high-volume production, which remains fundamental to large OEMs. But today, manufacturing efficiency must begin before components are produced to achieve productivity gains and cut time to market — which means that smart manufacturing or using data to drive decision making and propel production, must begin in development".

"The manufacturing costing function has sat in OEM design teams for many years, with design-for-manufacturing techniques, including process-simulation, evolving from computer-aided-design (CAD) model preparation to predicting and mitigating the hard realities of the shop floor. As soon as parts are prototyped, the digital twin can be enriched with real measurements for manufactured parts, which helps resolve process or component issues quickly".

Create and evaluate digital twins

One of the biggest benefits of putting effort and time into the early design and engineering phase is understanding what will happen when you take a design and start to manufacture it. Utilising CAE software tools from Hexagon, OEM’s can effectively create and evaluate digital twins of multiple designs using virtual prototypes, instead of having to build physical ones. Identifying the best functional design that can be manufactured, as opposed to taking the CAD and trying to make it work on the production floor, is a huge shift that saves time and money, reduces waste, and improves productivity.

"Design for manufacturing encompasses the capability to adjust and optimize design to make the manufacturing process right the first time. With digitization and simulation, companies can observe the whole manufacturing process. Combined with virtual 3D golden parts for performing real time comparisons, factory digitization enables a comprehensive measurement ecosystem. The product development phase and the manufacturing phase are linked. Applying digital intelligence and machine learning provides data that confirms the process and even can anticipate failures".

"Today’s successful automotive manufacturers are demonstrating the value of virtual prototyping as their innovation cycles shrink by successfully reducing time from design to production using a simulation-intensive approach. This foresight helps to reduce vehicle costs while anticipating and eliminating potential defects early to avoid costs and delays".

"Our recent Advanced Manufacturing Report revealed that almost three-quarters (71%) of business leaders are concerned about the lack of synergy between their design and manufacturing teams. Gains made by tearing down departmental walls are numerous, most notably more integrated system development and production, but doing so requires increasing supply chain collaboration and vertically integrated manufacturing", concludes Jordi Planell.

Lea este artículo en castellano.

El Clúster de Automoción y Movilidad de Aragón (CAAR) ha llegado a la mitad del año superando los 130 socios, en línea con la tendencia de crecimiento constante que ha mostrado desde su creación.

Ante el nuevo reto de los vehículos inteligentes y conectados de nuevas energías, SAIC Motor ha creado este conjunto de tecnologías originales, fundamentales y comunes, que sirve como base para todas las marcas del grupo, entre las que se encuentra MG.

La tercera generación del modelo se seguirá fabricando en la factoría de Sunderland (Reino Unido).

Toyota Motor Europe (TME) se ha asociado con la Fundación H2 Grand Prix (H2GP) para impulsar la educación STEAM (Ciencia, Tecnología, Ingeniería, Arte y Matemáticas) y promover la tecnología del hidrógeno entre los estudiantes.

Genesis Motor Europa ha anunciado que se adentrará en cuatro nuevos mercados europeos, marcando un nuevo capítulo en su expansión estratégica en la región y complementando su presencia actual en Alemania, Suiza y el Reino Unido.