AutoForm unveils its solution for BiW Assembly

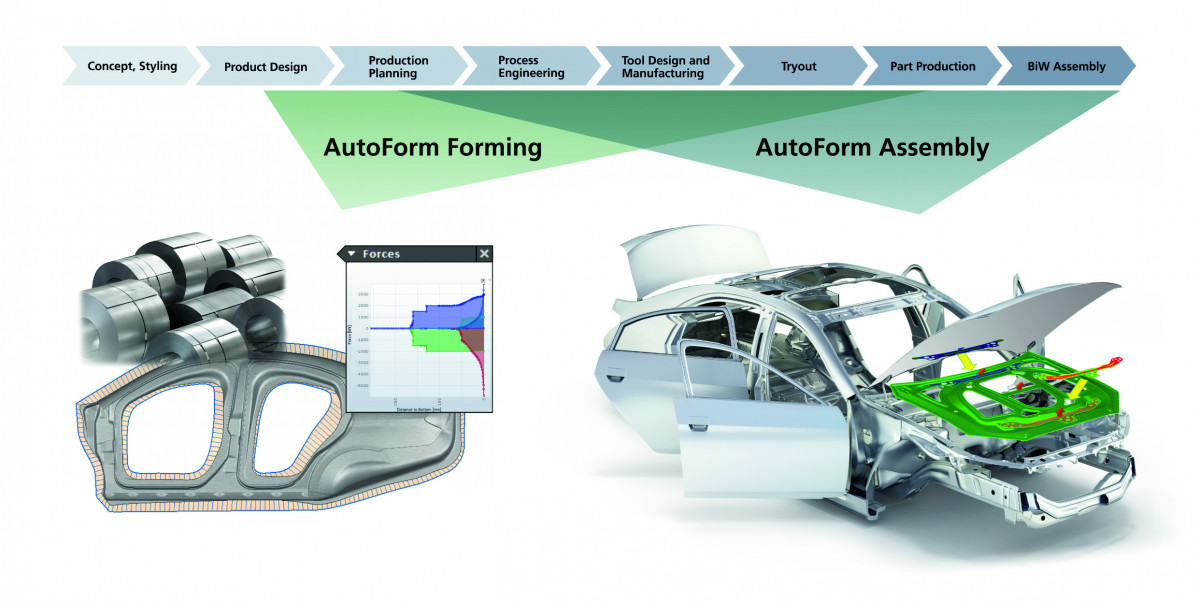

AutoForm Engineering, a global supplier of software solutions for stamping and BiW assembly processes, has unveiled its latest software solution AutoForm Assembly. This solution covers the BiW assembly process chain, combining all of the critical aspects of assembling parts. AutoForm Assembly enables users to address complex issues in the BiW assembly process before they can arise in production and expand digitalization. AutoForm’s solution for BiW assembly supports the entire BiW process chain, which covers early feasibility, process engineering and BiW production.

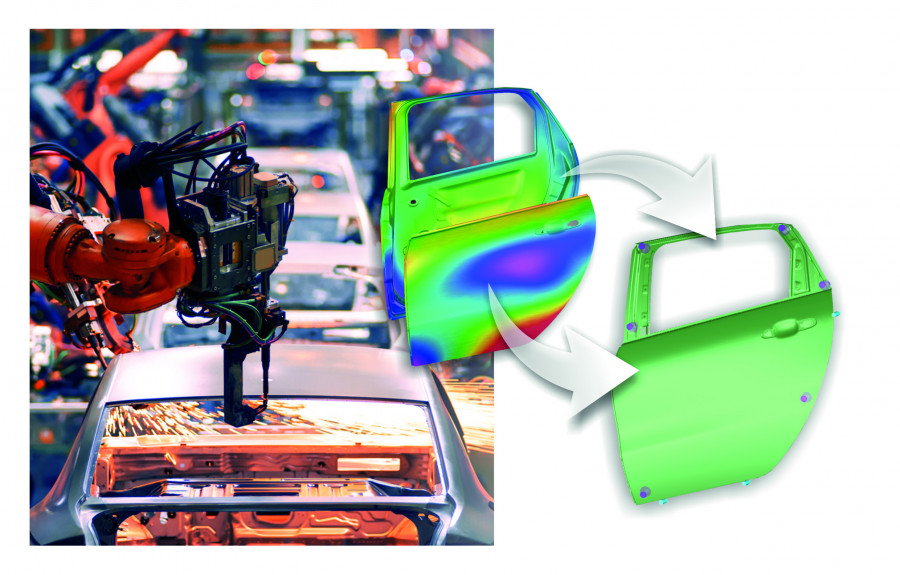

By implementing AutoForm software for the BiW assembly process, users can gain deep insight into the car body manufacturing process, quickly evaluate alternative part and assembly process designs, identify the causes of dimensional deviations and undertake effective countermeasures. The combination of AutoForm Forming and Assembly solutions covers the stamping and BiW assembly processes. With unique AutoForm Assembly capabilities, users can virtually set up the entire assembly process, including joining and hemming technologies. They can make process modifications easily by taking into consideration different part insertion orders, changes to pilot and clamping positions, and different sequencing of the joins.

AutoForm Forming and Assembly solutions cover stamping and BiW assembly processes.

With this software, they can achieve higher product maturity earlier in the development process and reduce the number of product modifications later in tryout and manufacturing. The software allows them to save on costs for tooling and equipment modifications as well as to reach higher process maturity and greater robustness at tryout and the start of the production.

Dr. Markus Thomma, CMO of the AutoForm Group, stated: “We are glad that we can now offer a unique and first to market software solution to users in the BiW area. For many years, AutoForm Forming has been the software of choice for part makers, tools shops and engineering service providers worldwide. Now, with AutoForm Assembly, we are expanding the covered manufacturing processes and offering a state-of-the-art software solution to customers in the field of BiW assembly. With AutoForm Assembly, they can achieve tangible benefits in their daily work in terms of both cost and lead time savings.”

Renault Group presentó el pasado 2 de julio ante los medios de comunicación su Plant Connect de su planta de Palencia y otras innovaciones en el marco del evento internacional Renault E-Tech Tour. Una información de Irene Díaz.

“Atrevido, elegante y propulsado por un sistema de propulsión 100% eléctrico”, tal y como lo describe la compañía, el modelo de acceso a la gama de la marca, que recientemente se ha presentado en el mercado europeo bajo el nombre Dolphin Surf y que también se vende en China como BYD Seagull, ya goza de una gran popularidad en Brasil.

Xiaomi ha anunciado el inicio de las ventas oficiales de su primer SUV, el Xiaomi YU7, que se posiciona como un SUV de lujo de alto rendimiento que pretende redefinir el lujo a través de un diseño avanzado, tecnología, experiencia de conducción y seguridad, creando un SUV avanzado que desafía lo ordinario. Xiaomi YU7 está disponible en tres versiones: Standard, Pro y Max.

Ford España ha lanzado el SupportBelt, un accesorio diseñado para mejorar la experiencia al volante de las personas que, debido a un cáncer de mama, una reconstrucción, mastectomía o ciertos tratamientos, sienten incomodidad a la hora de usar el cinturón de seguridad.

CRECEMOS ha llevado a cabo un encuentro en el Parlamento Europeo con los principales representantes institucionales y del sector privado para debatir sobre la revisión de los Reglamentos de Emisiones (LDV y HDV), el papel de los combustibles renovables en la descarbonización como una solución presente.